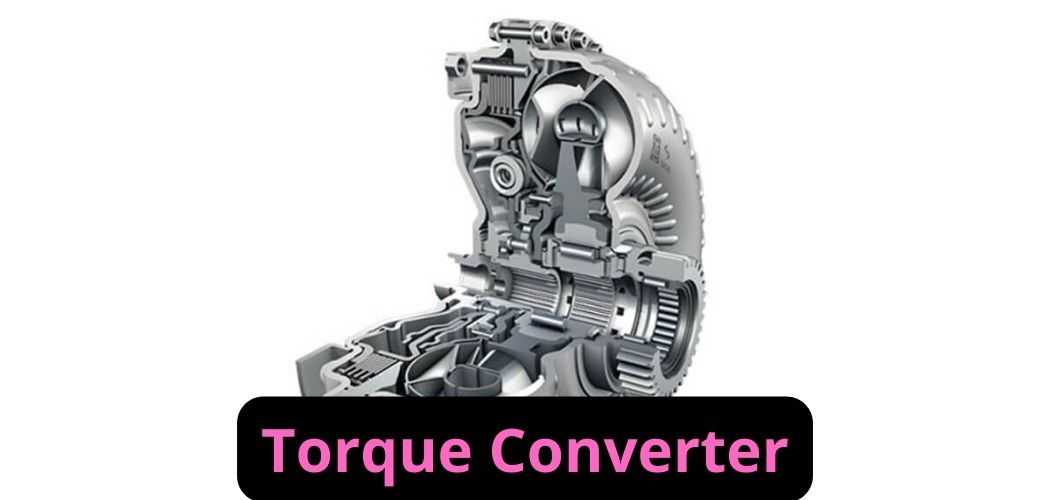

Torque Converter

The torque converter is an essential component of an automatic transmission, facilitating a smooth transfer of power from the engine to the transmission. It replaces the traditional clutch in a manual transmission, allowing the engine to continue running while the vehicle is stationary.

Share on Social Media:

What is a Torque Converter?

A torque converter is a critical component in an automatic transmission vehicle, serving as a medium to transfer engine power to the transmission. Its operation can be likened to two fans placed facing each other, where one pushes air towards the other, allowing the latter to spin without electrical power, simply through the action of the air. This basic principle involves the transmission of energy between a centrifugal pump and a turbine using transmission fluid as the catalyst. An apt analogy for its function would be two fans facing each other. The first fan is connected to a power source and blows air towards the second fan, which starts to spin upon receiving this moving air flow, even though it is unplugged, thereby synchronizing both.

The torque converter has four main components that facilitate this type of exchange:

Pump (also called the transmission case): This component rotates attached to the engine's crankshaft and activates upon starting the engine. It has curved blades or vanes that thrust the transmission fluid towards the turbine.

Turbine: The fluid propelled by the pump’s blades reaches those of the turbine, which is connected to the transmission. These blades, also curved, receive the fluid in a direction opposite to their rotation, enabling their movement. The fluid is then driven back towards the pump by the center part of the turbine, directed by the curvature of the blades or vanes.

Stator: This component, also known as the reactor, changes the direction of the fluid back towards the pump to minimize energy loss and thus increase the efficiency of the torque converter. It does this using a bearing that allows it to rotate in one direction (that of the engine), thereby forcing the change in the fluid’s direction of rotation.

Lock-up Clutch: This feature has become common in modern automatic transmissions, as it can disable the torque converter when necessary through control by the electronic control unit or ECU. It connects to the pump, and when engine torque input occurs, the fluid presses it against the pump, producing a rigid propulsion without slippage that resembles that of a conventional clutch. All these elements are enclosed within a sealed casing filled with transmission fluid, usually mineral oil.

Operation: When the driver starts the engine, the pump begins to rotate at low speed, projecting the fluid towards the turbine. However, the hydraulic energy generated by this projection is minimal, so the turbine remains stationary, allowing the engine to idle without moving the vehicle. As the driver accelerates, the pump speeds up, pushing the transmission fluid with greater force, generating more hydraulic energy, which in turn creates enough kinetic energy to start the turbine spinning. This process provides sufficient force to initiate the turbine's rotation.

The torque converter is always associated with an automatic gearbox. As the turbine accelerates the fluid towards the stator, which then changes the fluid’s rotation direction to match that of the pump (which is the same as the engine’s). The torque transmitted by the turbine is the sum of that transmitted by the pump through the fluid and the additional torque generated from the stator to the pump, which in turn is transmitted back to the turbine. The greater the rotational speed difference between the turbine and pump (slippage), the greater the torque differential between the input and output of the converter, becoming up to three times higher at the output.

As the rotational speeds become more aligned, the deviation of the transmission fluid's flow reduces, as does the additional thrust on the turbine. Thus, the torque ratio between the output and the input decreases, and the stator even begins to rotate in the same direction, allowing the additional thrust to disappear and no further increase in engine torque occurs. At this point, the torque converter starts to behave like a conventional hydraulic clutch. The rotation speed of the pump and turbine unify with a slippage of roughly just 2%.

Even if the driver accelerates abruptly from idle, the vehicle begins to move progressively as the slippage gradually decreases.

Advantages and Disadvantages

The torque converter offers several benefits, including no wear and tear and, consequently, a longer lifespan than the vehicle itself. It also significantly dampens torsional vibrations and ensures a smooth start due to the gradual reduction in slippage. The maintenance is minimal, requiring only a change of fluid approximately every 20,000 km. It also provides increased torque on inclines or in traction-demanding situations.

However, there are some drawbacks to consider. It cannot be coupled with a manual gearbox. There is higher fuel consumption due to energy loss from slippage, and the overall cost is higher.

Planetary Gears

Direct use of a torque converter in a vehicle provides very low efficiency at low speeds and cannot increase torque beyond three times. As a result, planetary gears are introduced, which allow for a very progressive change in torque.

Also known as epicyclic gears, they are operated via hydraulic or electronic systems that control brakes and clutches, which in turn direct the movement of the gears. At the center, a 'sun' or 'planet' gear spins around its axis. Meanwhile, 'satellite' or 'planetary' gears (housed in the carrier) connect with the sun, spinning around their respective axes and in the circuit formed around the central pinion or sun gear. The carrier rotates, initiating the rotation of the satellites meshed in the ring gear, as well as the entire epicyclic system.

When one of these elements is locked, the rest continue to spin, and motion is transmitted based on the selected transmission ratio. If two components of the system are locked, the entire system becomes locked, and the rotation speed perceived by the engine matches that of the system.

The possible gear ratios obtained in an epicyclic train depend on whether, when one of its elements spins, there is another element that reacts. Depending on the choice of the element that acts as the input or the one that reacts, four different ratios can be identified, corresponding to three possible gears and one reverse gear. To combine three or more speeds, combinations of epicyclic gears are commonly used. Automatic gearboxes employ combinations of two or three epicyclic trains, providing three or four forward ratios and one reverse.

The SocialPhy Torque Converter tool is an innovative online resource designed specifically for automotive professionals and enthusiasts. This tool serves a critical role in the analysis, design, and testing of torque converters, which are key components in automatic transmission systems. Here’s why using the SocialPhy Torque Converter tool is beneficial and why I highly recommend it:

Comprehensive Analysis Features

SocialPhy Torque Converter offers extensive analytical capabilities that allow users to perform detailed assessments of torque converter performance. It includes features for testing fluid dynamics, slip characteristics, and load capacity, providing a robust platform for understanding how changes in design affect overall performance.

Design Optimization

One of the standout features of this tool is its ability to help users optimize the design of torque converters for specific applications. Whether you're looking to improve fuel efficiency, increase torque output, or reduce wear and tear, SocialPhy provides the necessary tools to modify and enhance converter specifications to meet precise performance requirements.

User-Friendly Interface

Despite its advanced capabilities, the SocialPhy Torque Converter tool is designed with a user-friendly interface that makes it accessible even to those who may not have extensive technical background. Interactive diagrams, step-by-step guides, and customizable templates make it easier to navigate and utilize the tool effectively.

Real-Time Simulations

SocialPhy enables real-time simulations that mimic actual operating conditions. This feature is invaluable for conducting 'what-if' analyses and foreseeing the impact of different design choices without the need for costly physical prototypes.

Why Recommend the SocialPhy Torque Converter Tool?

- Increased Productivity: By streamlining the process of design and analysis, this tool significantly cuts down development time and expedites decision-making.

- Cost Efficiency: Reducing the need for multiple prototypes and extensive physical testing, the tool cuts down on development costs associated with traditional methods.

- Precision and Accuracy: Advanced algorithms ensure high precision and accuracy in simulations and analyses, leading to better outcomes and more reliable torque converter designs.

- Support and Updates: SocialPhy offers excellent customer support and regular updates to the tool, ensuring it stays at the cutting edge of technology and industry standards.

In conclusion, the SocialPhy Torque Converter tool is a must-have for anyone involved in the design or maintenance of automatic transmission systems. Its blend of powerful features, ease of use, and cost-effective benefits make it a standout choice, worthy of recommendation to professionals seeking to enhance their workflow and product quality.

Other very useful tools for SEO: